Purpose

This method statement for soil investigation described the boring and test procedures and required management control for the project pursuant to the requirements stipulated in the contract documents.

To define management’s objectives and standards for Sub-Soil Investigation.

Table of Contents

- Purpose

- Scope of Work

- Definitions and Abbreviation

- Specifications, Codes, & Standard

- Roles & Responsibilities

- Material

- Equipment

- Work Procedure – Method Statement for Soil Investigation

- Work Methodology

- Method of Advancing Borehole

- Laboratory Tests

- Quality Control

- Health, Safety and Environment

- Working Area

- Security

- Appendix/Attachment

Scope of Work

The main objective of this ground investigation program required for Sub-Soil Investigation. The entire investigation will be done in accordance with the ASTM standard practice. The investigation program included drilling boreholes and collecting soil samples at desired intervals for subsequent observation and laboratory testing.

The Scope of Works for the Soil Investigation are divided into two types of works:

Field Work

Borehole in Land

Field work will be carried out as follows:

Execution of Standard Penetration Test (SPT)

Collection of Disturbed Samples

Collection of Undisturbed Samples

Handling and Labelling of Samples

Ground Water Table Measurement

Making Borehole Log with relevant Field Data

Sample Dispatch to the Laboratory

Laboratory Work

The following laboratory tests will be carried out on soil samples in order to evaluate the

physical and mechanical properties of the sub-soil:

Unit Weight

Natural Moisture Content

Atterberg Limits and Plasticity Index

Particle Size Distribution (Sieve & Hydrometer)

Specific Gravity

Unconfined Compression Test

Direct Share Test

Consolidation Test

Chemical Analysis of Groundwater

Bulk density/ Density

Constant Head Permeability Test

Unconsolidated Undrained Tri-axial Compression Test (UU)

Definitions and Abbreviation

“SPT” means Standard Penetration Test.

Specifications, Codes, & Standard

Relevant specification is contained in Work Requirement, Section XII: Specification –

Particular Specifications, Part 02, Sub Clauses 3: Piling works (Cast-in-situ).

Laboratory tests are performed in accordance with ASTM as tabulated in Table 1:

| Test Item | Standard |

| Moisture content | ASTM D2216 |

| Liquid limits & Plastic limit | ASTM D4318 |

| Specific gravity | ASTM D854 |

| Particle distribution | ASTM D422 |

| Consolidation tests | ASTM D2435 |

| Direct Shear Test | ASTM D3080 |

| Unconfined Compression Test | ASTM D2166 |

| Unit Weight | ASTM D7263 |

| Unconfined Compression Test | ASTM D2166 |

| Tri-axial Compression Test | ASTM D2435 |

| Constant Head Permeability Test | ASTM D2434 |

| pH | ASTM D1293 & ASTM G51 |

| Sulphate Trioxide ASTM 0516 & BS 1337 | Sulphate Trioxide ASTM 0516 & BS 1337 |

| Chloride | ASTM 0516 & BS 1337 |

| Carbonate | ASTM 0513 & ASTM 1888 |

Normal practices, codes, standards and the requirements of the employer, government

agencies and regulatory stated in the contract documents.

Roles & Responsibilities

Proposed staff organizational chart is shown in Appendix-3

Material

MSDS of the Bentonite is shown in Appendix-4

Equipment

Site Equipment

The equipment for this operation shall be listed as tabulated in Table 2:

Tripod Rig for Percussion 1 set

Hydraulic Boring Machine 1 set

Winch Machine 1 set

Drilling Equipment 1 set

Drill Bit 2 sets

Sampling rods L=3m, L=1.5m, L=1 m (60 m)

Casing Pipe L=3m, L=1 m, L=0.5m m (10 m)

Thin – Walled tubes L=100cm; =73mm 20 tubes

Slurry Pump 1 set

SPT hammers 63.5kg 2 sets

Split – barrel samplers ASTM Standard 2 sets

Laboratory Test Equipment

Standard Sieves and shaker

Hydrometer

Liquid & Plastic Limits Apparatus

Specific Gravity Pycnometer

Consolidation Apparatus

Triaxial Compression Machine

Direct Shear (small)

Unconfined Compression Test

Drying Oven

Constant Head Permeability Test

pH, Sulphate Trioxide, Chloride,

Carbonate

Digital weighing balance

Vacuum

Work Procedure – Method Statement for Soil Investigation

Work Flow Chart

The work sequence of the Soil Investigation is described in the following work flow-chart:

Confirmation of Drilling Points ->Drilling of Holes->Collect Undisturbed

Sample->Establishment of SPT test->Collect Disturbed Sample->Levelling of the

Sample->Ground Water Level Measurement->Bore Log Data Recorded->Sample Send

to Laboratory->Lab Tests->Reporting

Work Methodology

The work procedure is described as follows:

Field Work

Confirmation of Drilling Points

The borehole will be topographically survey the locations and the elevations of

boreholes. The exact locations (X-Y coordinates) and elevations of points to be

investigated will be topographically measured in accordance with the instruction by the

consultant. Each Location are subjected to Employer/Engineer’s Approval.

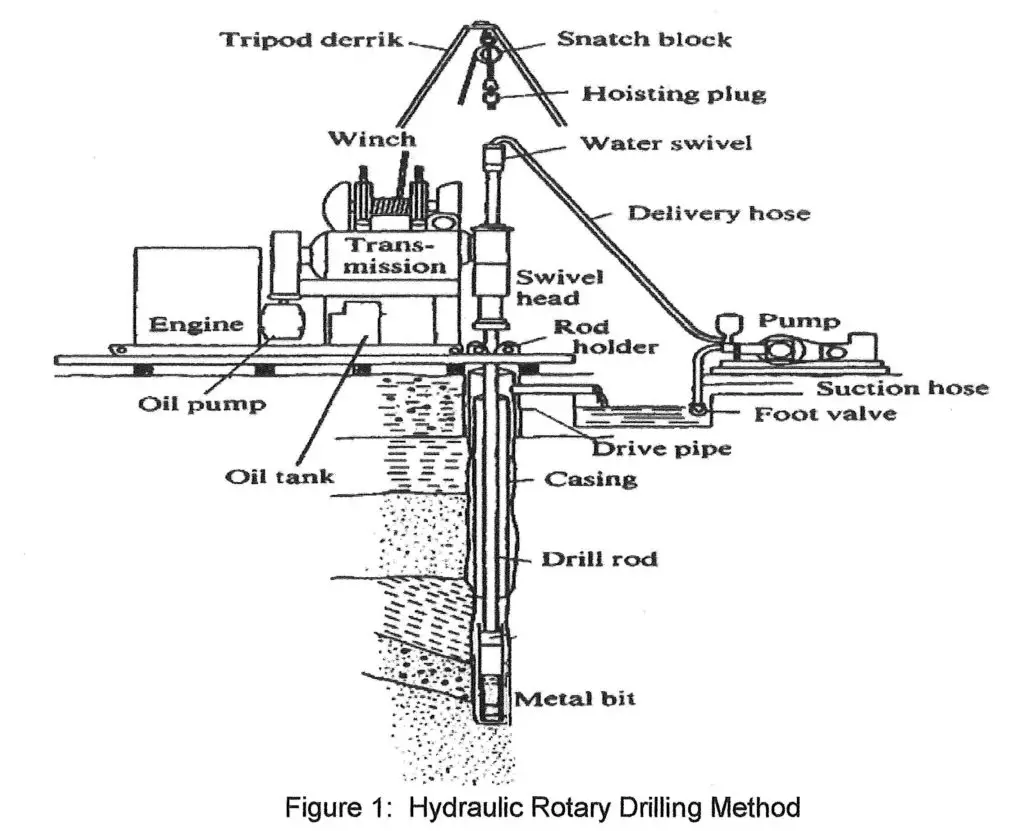

Method of Advancing Borehole

Drilling/ Boring Work in Land:

The boring shall be done by Rotary Percussion method with hydraulic rotation. The

boring is advanced by jetting water which is pumped through the hollow drilling rods.

Cuttings are removed from the hole by the circulating water.

The water is pumped from a small swamp mixture with bentonite with water and the soil-laden water from the borehole is discharged into the same reservoir, where the coarse materials settled out and from which the so- called ‘wet samples’ can be secured.

Straight flushing of the borehole is generally being done by high-pressure piston pump to remove the cutting material from the borehole.

The drilling fluid under pressure is introduced/jetted into the bottom of the borehole through the hollow drill rod.

The drilling fluid carries the cutting materials from the bottom of the borehole as it returns to the surface through the annular space between the drill rods and the walls of the borehole face.

In the uncased bore hole, it also serves to support the borehole face against collapsing. Settled cuttings in the circulation tank are removed and disposed off periodically. The disposal will be done by making a small swamp nearby and covered by the removed soil.

Uncased boreholes shall be drilled of 100mm dia. so that 75 mm dia. undisturbed samples can be obtained from cohesive soil layer. A 5m long temporary casing is being used for boring in land and water, depth of 10m or more, long casing in case of drilling in water. Bentonyte slurry shall be used for stabilization of borehole. After completion of the investigation all the boreholes will be backfilled.

Cuttings were removed from the hole by the circulating water. The drilling rods are moved up and down by pulling and slackening the rope and are at the same time rotated back and forth by means of a driller.

The water is pumped from a small swamp and the soil-laden water from the borehole is discharged into the same reservoir, where the coarse materials settled out and from which the so called ‘wet samples’ can be secured. Straight flushing of the borehole is generally being done by high-pressure piston pump to remove the cutting material from the borehole.

The drilling fluid under pressure is introduced/jetted into the bottom of the borehole through the hollow drill rod. The drilling fluid carries the cutting materials from the bottom of the borehole as it returns to the surface through the annular space between the drill rods and the walls of the borehole face.

In the uncased bore hole, it also serves to support the borehole face against collapsing. Settled cuttings in the circulation tank are removed and disposed off periodically.

Uncased boreholes shall be drilled of 100mm dia. so that 75 mm dia. undisturbed samples can be obtained from cohesive soil layer. A 5m long temporary casing is being used for boring in land and water, depth of 10m or more, long casing in case of drilling in water. Bentonyte slurry shall be used for stabilization of borehole.

After completion of the investigation all the boreholes shall be back filled.

Sequence of Boring

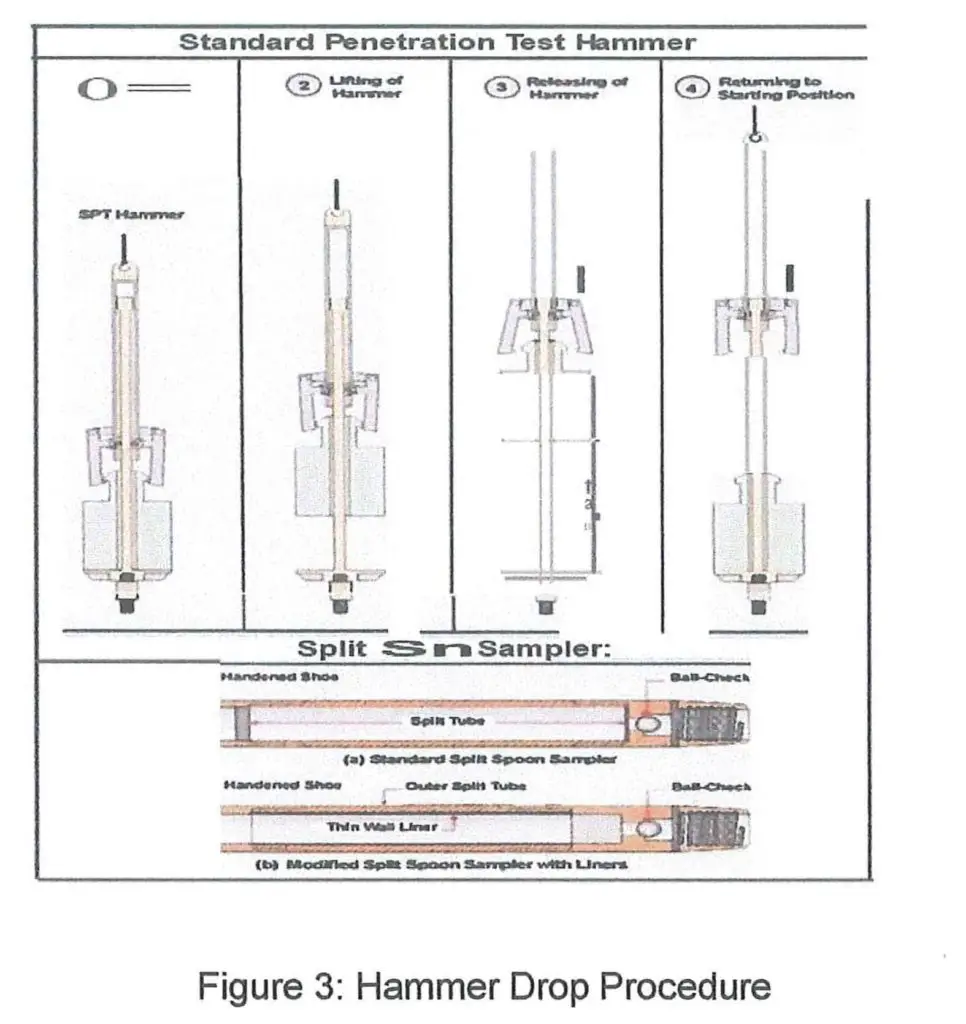

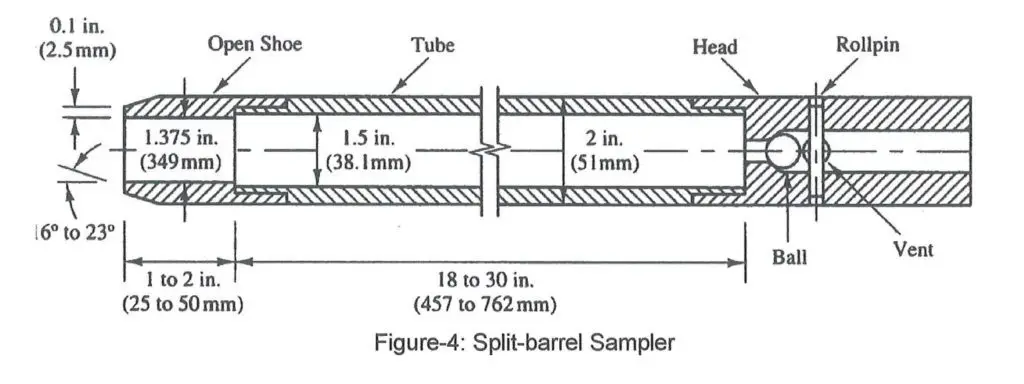

Performing Standard Penetration Test (SPT)

Standard penetration test is executed in all the bore holes at 1.5 m intervals. In this test,

a split-barrel sampler as specified in ASTM 01586 will be used to penetrate 45 cm (18″)

into the soil by drops of a hammer weighing 63.5 kg (140 lbs) falling freely from a height

of 76 cm (30″). The number of blows required for penetration of each 15 cm (6″) will be

recorded in the logs of borings shown in Fig 3.

The number of blows required for the middle 30 cm ( 12″) penetration will be taken as the standard penetration resistance (SPT N-value). Soil sample in the spilt spoon of the sampler will be collected and preserved in airtight container with proper identification and transported for laboratory testing.

Collection of Disturbed Sample

The disturbed soil samples shall be systematically collected and identified by visual soil

classification according to the standard of Unified Soil Classification (USCS) before putting in the plastic zipper bag to preserve natural water content.

Then label project details, location, borehole, date, sample number and depth before delivery to laboratory for any testing.

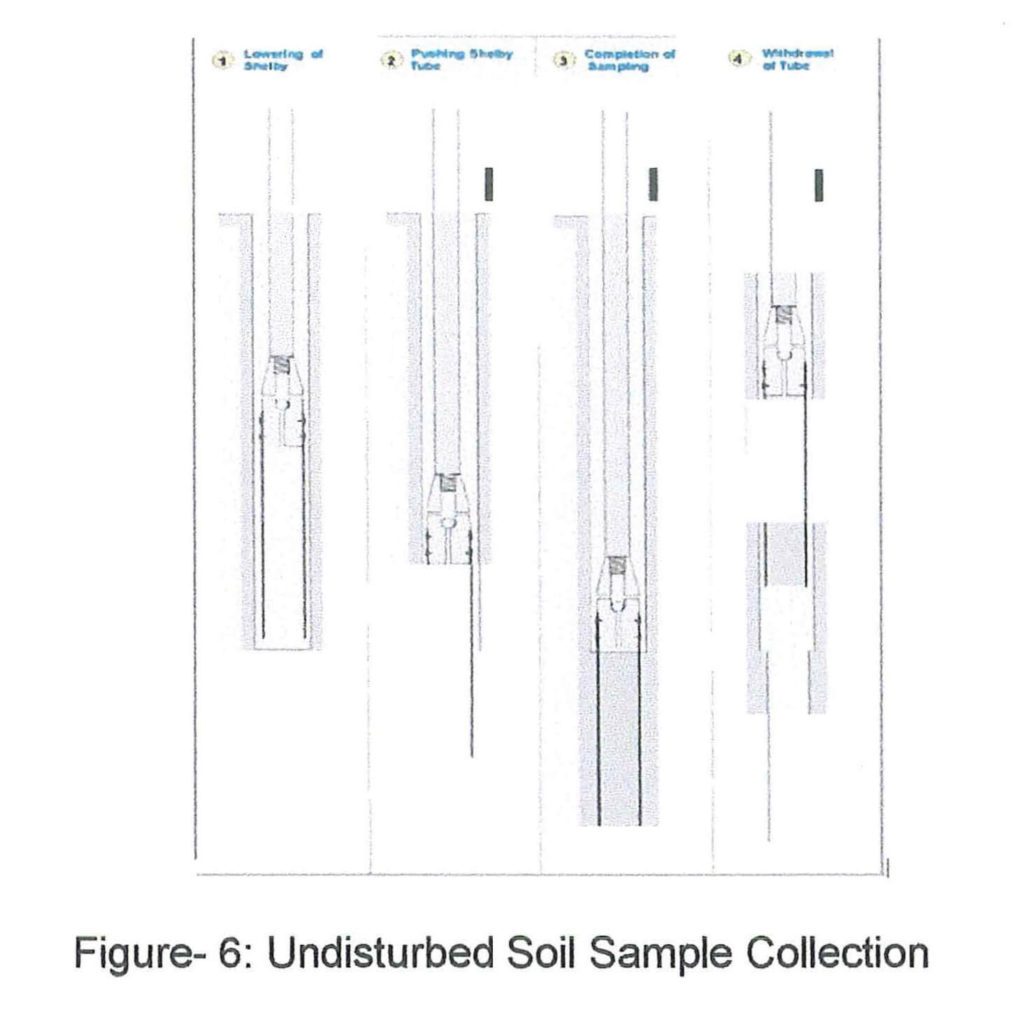

Collection of Undisturbed Sample

Undisturbed sample shall be collected in good quality thin walled seamless shell by tubes conforming to from cohesive soil strata. The size of thin walled sampler shall be such that a sample having a minimum size of 75 mm diameter and 450 mm length can be recovered.

The top and bottom of a sample will be indicated clearly on that sample tube to facilities the laboratory testing in proper orientation. However, SPT is not done at the points where undisturbed samplings are done. Undisturbed samplings are performed using thin wall samplers; however, thin wall samplers will not be used for hard soil.

Undisturbed sampling shall be carrying out with proper handling and labeling of sample

with following condition:

a. Immediately after being taken from the borehole, it shall be cut at about 25 mm height or more (if disturbed soil covered). Several layer of molten wax shall have applied to each end to give a plug about 25 mm thick.

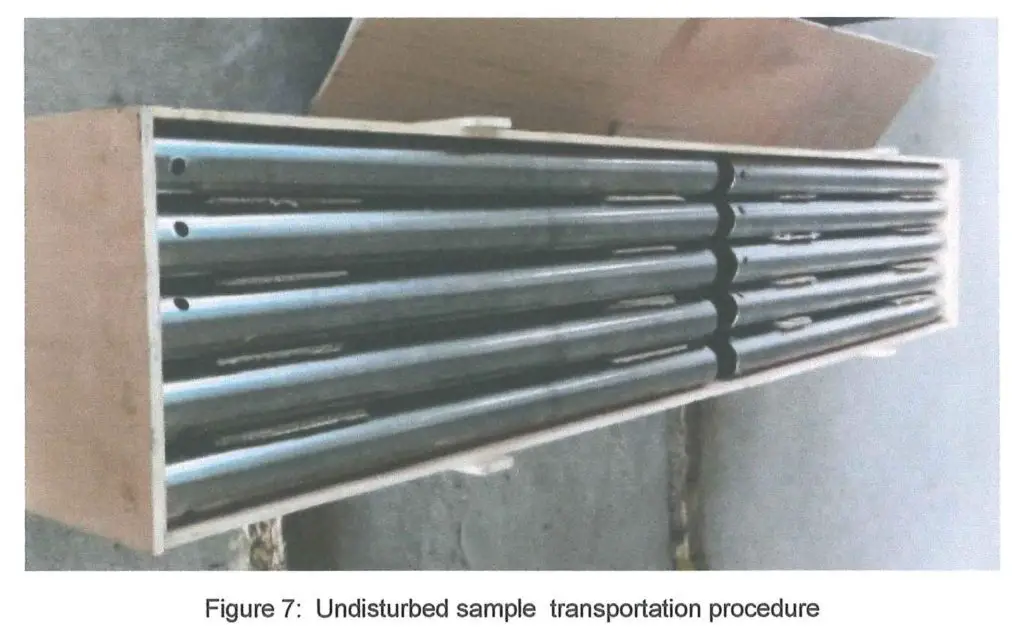

b. A label bearing the number of sample, borehole number, bore hole details location, date etc. shall place attached by transparent tape on the Shelby tube also inside the container. This container shall go to a local laboratory for extrusion and proper packing before dispatching to assigned laboratory for testing. Sample shall be dispatched to the laboratory as soon as possible.

Laboratory Tests

Sieve and Hydrometer Analysis

Particle size distribution is determined by means of sieving, hydrometer tests, or both.

The percentage of weight of the various particle sizes in excess of 74 Lm is determined

by sieving through a set of standard sieves using an electric shaker capable of horizontal

and vertical motions. Wire sieves of up to and including opening size of 2 mm, is used.

Plate sieves with opening size of more than 2 mm are used when more than 5 % of the

weight of the specimen is retained on the 2 mm sieve.

When there is a considerable amount of particles smaller than 7 4 μm, the sieving is

complemented by a hydrometer test in which the sample is mixed with water and stirred

for about 15 minutes. An additive will used to prevent flocculation of the soil particles.

After mixing, the density of the water-soil slurry is measured at fixed time intervals, and

the particle size distribution of the sediment particles will determined. This test is

performed in accordance with ASTM D 422.

Atterberg Limits

The Atterberg limits refer to arbitrarily defined boundaries between the liquid and plastic

states (i.e., liquid limit, WL and between the plastic and brittle states i.e., plastic limit,

Wp), of fine-grained soils.

They are expressed in percentage water content. The range of water contents over which a soil behaves plastically is termed the Plastic Index and corresponds to the numerical difference between the liquid and plastic limit (i.e., WL-Wp).

Tests to determine the Atterberg limits are performed on soil samples of cohesive material.

The soil is dried and then ground into separate grains using a mortar. The soil grains larger than 425 μm size are removed by sieving. The soil is then thoroughly mixed with different quantities of distilled water. The liquid and plastic limits of the soil are then determined in accordance with ASTM D4318.

Specific Gravity

Specific gravity of the soil particles is determined by means of a stoppered bottle pycnometer with a volume of 50 ml. The bottle is filled with distilled water and weighed.

The unit weight of the water can then be determined.

Then the bottle is partly filled with distilled water in which 10 g of dry crumbled soil is mixed. Entrapped air is removed from this mixture by subjecting the contents of the bottle to a vacuum. The bottle is then completely filled up with distilled water and weighed.

The unit weight of the particles of the soil can be computed with these data. The weights of the bottle and contents are determined at a temperature of 20 °C. This test is performed in accordance with ASTM 0854.

Natural Moisture Water Content

The water content is determined by oven drying selected moist/wet soil material for at least 24 hours to a constant dry mass at a temperature of 105 °C. The loss in weight of the sample due to drying represents the weight of the moisture of the soil.

The moisture content of the soil is presented as percentage of the dry weight of the soil.

This test is performed in accordance with ASTM 02216.

Unconfined Compression Test

Unconfined compression test will conducted in accordance with ASTM D2166. The tests will performed by compressing cylindrical samples to failure. Failure generally occurs when the greatest ratio of shear stress to shear strength occurs. The cohesion (c) of the sample is taken as half the unconfined compressive strength.

Direct Shear Test

A direct shear test is a laboratory or field test used to measure the shear strength properties of soil in accordance with ASTM D 3080.

The test is performed on three or four specimens from a relatively undisturbed soil sample. A specimen is placed in a shear box which has two stacked rings to hold the sample; the contact between the two rings is at approximately the mid-height of the sample. A confining stress is applied vertically to the specimen, and the upper ring is pulled laterally until the sample fails, or through a specified strain.

The load applied and the strain induced is recorded at frequent intervals to determine a stress-strain curve for each confining stress. Several specimens are tested at varying confining stresses to determine the shear strength parameters, the soil cohesion (c) and the angle of internal friction, commonly known as friction angle.

The results of the tests on each specimen are plotted on a graph with the peak (or residual) stress on the y-axis and the confining stress on the x-axis. The y-intercept of the curve which fits the test results is the cohesion, and the slope of the line or curve is the friction angle.

Consolidation Test

The standard oedometer test, also referred to as consolidation test (ASTM 02435 – 04) or one-dimensional compression test, is a classical laboratory test that allows characterizing the soil stress-strain behavior during one-dimensional compression or swelling. Carried out on saturated soil specimens, this test ·can be used to determine consolidation and swelling parameters.

The standard oedometer test is one of the most commonly used tests in geotechnical laboratory testing program. Consolidation device (including ring, porous stones, water reservoir, and load plate), Dial gauge (0.0001 inch = 1.0 on dial), Sample trimming device, glass plate, Metal straight edge, Clock, Moisture can, Filter paper.

Consolidation of a saturated clay soil occurs due to expulsion of water under a static, sustained load. The consolidation characteristics of soils are required to predict the

magnitude and the rate of settlement.

Unit Weight

Unit weight test will be conducted in accordance with ASTM 07263. Unit weight of soil is

usually determined from a core sample which is taken by driving a metal corer into the

soil at the desired depth and horizon.

This gives a soil sample of known total volume.

From this sample the Unit weight of soil can be determined.

Unconsolidated Undrained Tri-axial Compression Test (UU)

The tri-axial test is one of the most common testing methods for determining the shear

strength of soils. Tri-axial Compression Test which is conducted in accordance with ASTM 02435 is a test in which a cylindrical specimen of soil or rock encased in an impervious membrane is subjected to a confining pressure and then loaded axially to failure in compression.

For the UU test, the specimens (assumed to be saturated prior to test) are subjected to a

confining fluid pressure in a tri-axial chamber. Once the specimen is inside the triaxial

cell, the cell pressure is increased to a predetermined value by rotating the knob, and the specimen is brought to failure by increasing the vertical stress by applying a constant rate of axial strain.

Saturation and consolidation are not permitted to keep the original structure and water content of sample untouched.

Pore pressures are not measured during this test and therefore the results can only be interpreted in terms of total stress. These tests are generally carried out on three specimens of the same sample subjected to different confining stresses.

Since all specimens are supposedly saturated the shear strength are similar for all tests. The results of the test are plotted as curves of principal stress difference against strain. For conditions of maximum principal stress difference (taken as failure) Mohr circles are plotted in terms of total stress.

Constant Head Permeability Test

The constant head permeability test involves flow of water through a column of cylindrical soil sample under the constant pressure difference. The test is carried out in the permeability cell, or permeameter, which can vary in size depending on the grain size of the tested material. The soil sample has a cylindrical form with its diameter being large enough in order to be representative of the tested soil.

As a rule of thumb, the ratio of the cell diameter to the largest grain size diameter should be higher than 12 (Head 1982). The usual size of the cell often used for testing common sands is 75 mm diamater and 260 mm height between perforated plates.

The testing apparatus is equipped with a adjustable constant head reservoir and an outlet reservoir which allows maintaining a constant head during the test. Water used for testing is de-aired water at constant temperature. The permeability cell is also equipped with a loading piston that can be used to apply constant axial stress to the sample during the test. Before starting the flow measurements, however, the soil sample is saturated. During the test, the amount of water flowing through the soil column is measured for given time intervals.

Bulk Density/Dry Density

Bulk density/ dry density in accordance with ASTM D653 by the core method offers the

opportunity to obtain bulk density information. A metal cylinder is pressed or driven into

the soil. The cylinder is removed, extracting a sample of known volume. Alternatively, for

subaqueous samples taken as vibracores and opened by cutting, a plastic syringe with the end removed is used to collect a mini-core.

The plunger can be fixed at the 10-ml volume mark and the syringe gently pushed into the split vibracores sample to collect a known volume of sample. The moist sample weight is recorded. The sample is then dried in an oven and weighed.

Chemical Analysis of Groundwater

Chemical analysis of groundwater includes pH, Sulphate Trioxide, Chloride and Carbonate content analysis. ORION AQ3700 Colorimeter was used for these tests. pH is conducted according to ASTM D1293 for water & ASTM G51 for soil.

Sulphate Trioxide analysis is conducted according to ASTM DS 16 for water & BS 1337 for soil. Chloride is conducted according to ASTM D516 for water & BS 1337 for soil. According to ASTM

1888 for water & ASTM D513 for soil, carbonate content analysis is conducted.

Quality Control

During the execution of Additional Soil Investigation, Joint Inspection by the Contractor and the Engineer will be carried out on the main activities of this investigation work.

Task Risk Assessment

| Task | Risk Assessment |

| Confirmation of Drilling Points | When boring will be done under water, water shall be removed for drilling. |

| Drilling of Holes | If top layer is soft, bore hole will collapse. So, casing pipe will be used up to soft layer. |

| Collection of Undisturbed Sample | If the edge of Shelby tube is not so sharp, undisturbed sample will be disturbed. |

| Establishment of SPT Test | If the edge of Split Barrel is not so sharp, proper SPT cannot be taken. |

| Collection of Disturbed Sample | If the edge of Shelby tube is not so sharp, sample will be disturbed. |

| Labelling of Sample | If sample is not properly labelled, the depth of the sample will not be understandable. |

| Measurement of Ground Water Level | If it rains, measurement of ground water table will be affected. |

| Recording of Bore Log Data | Supervisor must be experienced in recording SPT and visual classification. |

| Sending Sample to Laboratory | Undisturbed sample will be sent in wooden packed box.Disturbed sample will be sent in plastic box. |

| Lab Tests | In lab test measurement should be taken carefully especially balance weight, consolidation and unconfined compression. |

| Reporting | In the reporting section, all field and lab data will be compiled together and geotechnical report will be prepared. |

During the process,the special action would be taken carefully to avoid the above mentioned TRA .

Health, Safety and Environment

The daily inspection will be conducted by Safety Staff, respective section supervisors and maintenance personnel as part of their responsibilities. Continuous inspection shall involve noting apparent or potential hazardous conditions and unsafe acts and either correcting it immediately or making a report to initiate a corrective action.

Respective section supervisors shall ensure that all tools, machines and equipment are properly maintained and safe for use. Safety induction will be implemented to all employees prior to working.

a. Employees must wear helmet at all time during working.

b. Employees who work on high must wear a safety belt.

c. Working under thunderstorm will not be allowed.

d. Employees who work near traffic must wear a reflective vest.

The work shall be carried out with sufficient environmental protection.Working platforms

or walkway shall be clean, not slippery, and free from debris.

Working Area

The boring location layout has been approved.

Security

Restriction for the access of all third parties will be implemented to avoid any incident

during this investigation works.

Appendix/Attachment

Attachment 1 : Inspection and Test Plan for Soil Investigation

Attachment 2: Inspection Sheet for Soil Investigation

Attachment 3: Work Staff Organizational Chart for Soil Investigation

Attachment 4 : MSDS of the Bentonite for Soil Investigation

Attachment 5: Test certificates/calibration certificates of equipment for Soil Investigation

tag: # Method Statement for Soil Investigation