Table of Contents

Method Statement for Crimping Aluminum Profiles

Aluminum profile crimping is a method of joining aluminum profiles together without welding. This technique is commonly used in the construction industry for building aluminum doors, windows, curtain walls, and other structural components. Proper crimping is essential to ensure that the aluminum profiles are securely joined and that the overall structure is stable and durable.

Tools Necessary

Before starting work, the following tools must be set up:

- Allen key

- measuring tape

- pencil

- spanner

- masking tape

Health and Safety Requirements

At the time of clamping and crimping, keep your hands away.

Use the appropriate tool to adjust the level.

Always wear gloves, safety glasses, and shoes.

At the time of clamping and crimping, keep your hands away.

In order to prevent products from scratching, any jewelry (including rings, watches, bracelets, and other accessories) must not be worn.

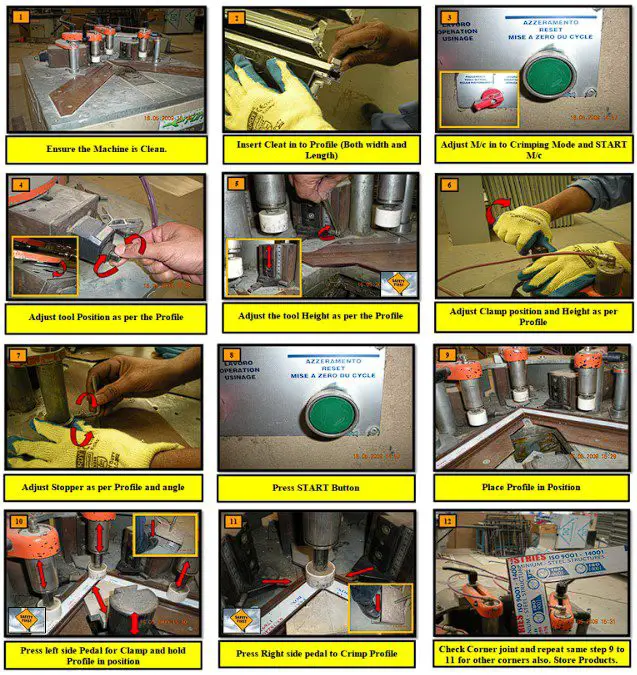

Work Instruction for Crimping Aluminum Profile

Make sure the equipment is clean.

Add the cleat to the profile (both in width and length).

Set on Crimping Mode, the machine, then turn it on.

Adapt the tool’s position to the profile.

Heighten the tool in accordance with the profile.

Adapt the height and position of the clamp to the profile.

Adjust the stopper according to profile and angle.

Push the START button.

Set the profile in the position.

Hold the profile position using the left side pedal for the clamp.

To crimp the profile, use the right-side pedal.

Check the corner joint, then repeat steps 9 through 11 for the other corners.

In order to prevent scratches and other damage, store products carefully.

Quality Control Measures

After completing the crimping process, inspecting the crimps to ensure they meet the necessary quality standards is important. Acceptance criteria for crimping aluminum profiles may vary depending on the specific application. However, some general quality control measures include visually inspecting the crimps for any defects, testing the strength of the joints, and keeping a record of the crimping results.

Maintenance and Care of Crimping Tools and Equipment

It is important to perform regular maintenance to ensure that your crimping tools and equipment remain in good condition. This may involve cleaning the equipment after use, lubricating moving parts, and replacing worn or damaged components. You should also inspect the tools and equipment before and after each use to ensure that they are functioning correctly.

Conclusion

In conclusion, crimping aluminum profiles is a valuable technique for joining aluminum profiles without welding. By following the method statement for crimping aluminum profiles, you can ensure that the crimps are high quality and that the overall structure is stable and durable. By properly preparing the profiles, using the correct tools and equipment, and following proper crimping techniques, you can ensure that the aluminum profiles are joined securely and that the overall structure is safe and long-lasting.

If you have any questions or concerns about crimping aluminum profiles, it is essential to consult with a professional who has experience in this area. They can guide the specific tools, techniques, and quality control measures required for your specific application.

Overall, by following the steps outlined in this comprehensive method statement for crimping aluminum profiles, you can ensure that your crimped aluminum profiles are of high quality and that your overall structure is stable and durable.

FAQs

What is crimping, and how does it differ from welding?

Crimping is a process of joining two materials, such as aluminum profiles, by compressing them together. This process creates a tight and secure connection without the need for heat or additional materials. Welding, on the other hand, involves melting the two materials together with the use of high heat and a separate welding material.

What are some benefits of using crimped aluminum profiles in construction?

Crimped aluminum profiles offer several advantages in construction, including:

High strength and durability: Crimped aluminum profiles can withstand high loads and stress without deforming or breaking.

Corrosion resistance: Aluminum profiles are naturally resistant to corrosion, making them ideal for outdoor and marine applications.

Lightweight: Aluminum is much lighter than steel or other metals, making it easier to handle and transport.

Aesthetic appeal: Crimped aluminum profiles have a sleek and modern look that can enhance the overall appearance of a structure.

What are some common mistakes to avoid when crimping aluminum profiles?

Some common mistakes to avoid when crimping aluminum profiles include the following:

Using improper tools or equipment

Applying too much or too little force during crimping

Failing to properly align the profiles before crimping

Using damaged or worn crimping tools

Neglecting to inspect the crimped connection for defects or weaknesses

How do you ensure that crimped aluminum profiles meet necessary quality standards?

To ensure that crimped aluminum profiles meet necessary quality standards, it is important to follow proper crimping techniques, use high-quality materials, and inspect the connections for defects or weaknesses. It is also recommended to consult with a professional with experience in crimping aluminum profiles to ensure that the process is done correctly and to the appropriate standards.

What are some safety precautions to take when crimping aluminum profiles?

Some safety precautions to take when crimping aluminum profiles include:

Wearing appropriate personal protective equipment, such as safety glasses and gloves

Ensuring that the work area is well-ventilated

Avoiding distractions and focusing on the task at hand

Following all manufacturer instructions for crimping tools and equipment

Using caution when handling sharp edges or corners on the aluminum profiles

Can crimping be used with other materials besides aluminum?

Yes, crimping can be used with various materials, including copper, brass, and stainless steel. However, the specific crimping tools and techniques may vary depending on the material being used.

How often should crimping tools and equipment be inspected and maintained?

Crimping tools and equipment should be inspected and maintained regularly to ensure that they are in good working condition and that the crimped connections are of high quality. The frequency of inspections and maintenance will depend on the specific tools and equipment being used and the frequency of use.

Can crimped aluminum profiles be disassembled if necessary?

In most cases, crimped aluminum profiles cannot be disassembled without causing damage to the profiles themselves. Therefore, it is important to carefully plan and measure the profiles before crimping to ensure they are in the correct position and orientation.

What types of structures are best suited for crimped aluminum profiles?

Crimped aluminum profiles are suitable for a wide range of structures, including:

Curtain walls

Doors and windows

Roofs and facades

Greenhouses

Solar panel frames

Furniture and fixtures

Is it possible to crimp aluminum profiles without using a crimping machine?

While it is technically possible to crimp aluminum profiles without using a crimping machine, it is not recommended. Hand crimping tools or other improvised methods may not provide enough force or precision to create a secure and reliable connection. Using improper tools or techniques can also damage profiles or injury. It is best to use a proper crimping machine and follow recommended techniques for the best results and to ensure safety.

tag: Method Statement for Crimping Aluminum Profiles