Table of Contents

What is Method Statement for Pressurization Fan Installation?

The Method Statement for Pressurization Fan Installation outlines the procedure for installing pressurization fans in a concise and clear manner. It includes steps such as identifying the installation location, preparing the area, ensuring electrical connections are in place, securely mounting the fans, and conducting tests to verify their functionality.

Safety measures and quality control checks are also emphasized throughout the process to ensure a successful and reliable installation.

Scope

In accordance with the Project Specifications, this method statement describes the storage, handling, and installation of pressurization fans and their accessories.

Application

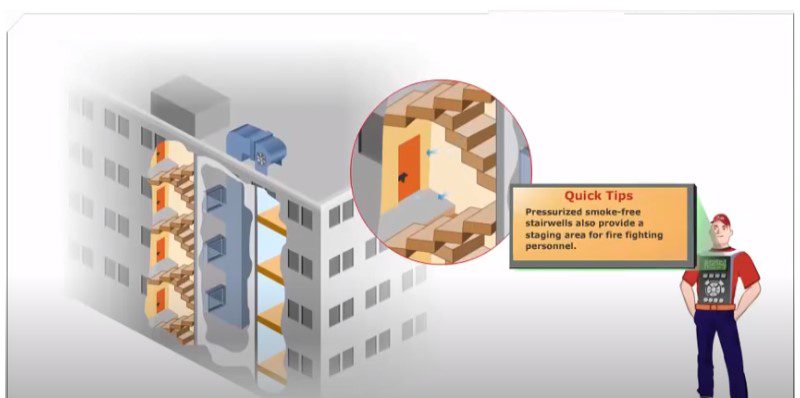

Pressurization of the lift wells, cores, and staircases

Material

Pressurization fans

Fasteners for supports, such as threaded rods.

flexible connections for ducts.

cables, devices, and accessories for electricity.

Method

Receiving

All Fans must be examined upon arrival at the job site for quantity, kind, and model number, as well as physical damage. Any inconsistencies must be reported to the supplier.

Upon completion of the inspection, the fan must be carefully stored and covered for protection.

The site must be cleared of any materials discovered to be damaged or unsuitable for the project’s requirements. Until then, the damaged or non-compliant item must be clearly marked and kept in a separate location to avoid unintentional usage.

Storage

The fans must be cautiously and gradually lowered to the ground while unloading. According to the size of the fan, enough workers will be engaged. The fans will be sorted by model and size and stacked appropriately for simple retrieval upon completion of receiving QC inspection.

Fans must be kept in well-ventilated, covered storage areas on a flat surface.

When applicable, the manufacturer’s directions must be rigorously followed.

Ensure that the bottom fan packing is not destroyed while stacking the fans.

As required, the storekeeper will be in charge of record maintenance and storage.

Preparation

Verify and ensure that all installation drawings are up-to-date and approved for construction.

For Floor Mounted Fans

Check the fan’s foundation to ensure it is in accordance with the approved drawings.

Inspect the area surrounding the foundation and, if applicable, ensure that all sides of the fans are accessible.

Check the foundation surface to make sure it is even and smooth to prevent the accumulation of dust.

Prior to the installation of fans, the foundation surface must be cleaned.

On the foundation, note where the fan is located.

As per approved drawings and submittals, fix the anti-vibration mounts/pads where applicable.

For Ceiling Suspended Fans

Verify and ensure that clearance and appropriate access are available at the installation place.

Mark the support points in the slab in accordance with the manufacturer’s specifications or approved drawings, and then fix the approved anchor fasteners.

According to the manufacturer’s directions, install the hanger rods and supports.

As applicable and in accordance with permissions, provide anti-vibration isolators.

Assure simple access and enough space for fan/motor maintenance and removal.

Installation

Floor Mounted Fans

Using a hand trolley, forklift, or crane, as applicable, move the fans safely to the place of installation. For safe shifting and installation, sufficient people will be engaged as required.

Make sure the appropriate fan is shifted to the installation place.

Make sure the orientation of the air inlet and outlet connections matches the approved drawings.

According to approved drawings or manufacturer’s instructions, attach the flexible duct connector to the fan’s inlet and outlet.

The fan is positioned correctly on the foundation with the appropriate anti-vibration mounts (if applicable).

The fans will be leveled correctly and parallel to the walls of the room and other installations.

During installation, hoisting, and relocating, fans must be inspected once more for any damage.

The fans’ interiors should be cleaned.

While installing the fans, follow the manufacturer’s directions.

For Ceiling Suspended Fans

Using a hand trolley, forklift, or crane, as applicable, move the fans safely to the place of installation. For safe shifting and installation, sufficient people will be engaged as required.

Make sure the appropriate fan is shifted to the installation place.

Make sure the orientation of the air inlet and outlet connections matches the approved drawings.

According to approved drawings or manufacturer’s instructions, attach the flexible duct connector to the fan’s inlet and outlet.

Carefully raise the fan into place on the supports. Engage the required number of people and tools to ensure a secure installation.

In coordination with other services and approved drawings, assess the installation’s level.

As soon as the levels are complete, cut and trim the support rods. Allow 25mm extra in support rod length for last-minute adjustments. Threaded rod ends will be primed with zinc.

Remove any burrs and jagged edges.

Fans must be inspected by QA/QC inspector once more for any damage sustained during hoisting, relocation, and installation.

The fans’ interiors should be cleaned.

While installing the fans, heed the manufacturer’s directions.

Seal any exposed ends.

Electrical and Airside Connections

Connections on the airside

Ductwork connections must be made in accordance with approved shop drawings.

According to approved drawings, provide the appropriate support.

Fans must not be affected by ducting weight.

Ensure that the inner fan area is clean before making the final connections to the fans, particularly the fan impeller.

Electrical Connections

As per the approved drawings, electrical power connections must be made.

According to the approved method statement, cables must be installed, terminated, and tested.

BMS interfacing

BMS interfacing must be carried out in accordance with the specifications.

Inspection

According to the installation checklist and the manufacturer’s instructions, a QC inspection must be performed.

For the consultant’s inspection, a request for a work inspection must be made.

Inspection must be documented using the format that has been approved.

Safety

In accordance with the approved project safety plan and process, all safety precautions must be taken.

For the installation of fans, only qualified and experienced professionals should be engaged.

PPE such as safety helmets, safety shoes, harnesses, gloves, and other items are required for anyone working on the installation.

All safety procedures must be observed, and the safety officer must check and ensure this.

All scaffolding and ladders used on the job site must have properly signed tags, which the safety officer must check and ensure.

Reference

Catalog from a manufacturer

Approved submittals

Approved shop drawings

Project Specifications

Records

Request for Work Inspection, properly signed by the Consultants.

Signed off Fan’s installation checklist.

Attachments

Checklist for installing pressurization fans.

tag: # Method Statement for Pressurization Fan Installation