Table of Contents

A septic tank method statement is essential to ensure that the installation or maintenance process is carried out safely, efficiently, and effectively. The statement also ensures that the installation or maintenance work complies with all relevant laws and regulations.

Septic tanks are crucial components of any property’s waste management system. They are underground chambers that store wastewater from bathrooms, kitchens, and laundry rooms. The septic tank method statement outlines the procedures and precautions required during the installation and maintenance of these tanks.

This article will provide an in-depth look at septic tank method statements, their importance, and what to include in them.

Introduction

Septic tanks are designed to hold and treat wastewater from residential or commercial properties that are not connected to the main sewage system. A method statement is a comprehensive document that outlines the specific procedures and precautions that need to be followed during the installation or maintenance of a septic tank.

Planning and Preparation

- Site survey and assessment

- Permits and approvals

- Equipment and materials

Before any installation or maintenance work can begin, a site survey and assessment need to be conducted. This survey helps to determine the suitability of the site for the installation of the septic tank.

Permits and approvals are also required before any work can commence. These permits vary depending on the location and may include planning permission, building permits, and environmental permits.

The equipment and materials needed for the installation or maintenance work need to be sourced and prepared in advance.

The Step-by-Step Process for Designing a Septic Tank

Septic Tank Design

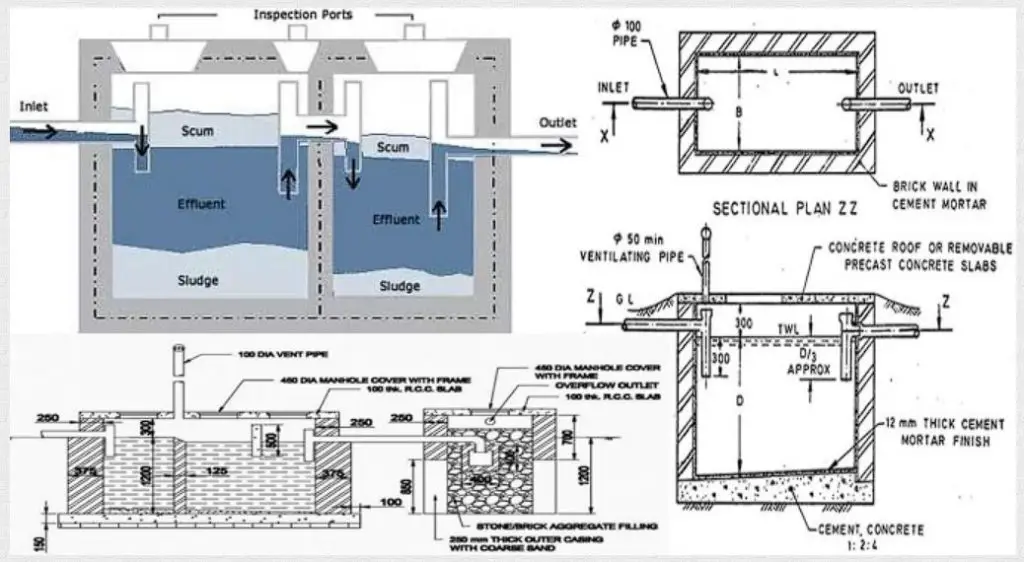

Septic tank capability is primarily based on the number of individuals who utilize the tank as well as the interval of dirt extraction. In general, dirt should be expelled every two years. 130 liters to 70 liters per head are assumed to be the tank’s liquid storage capability. 130 ltr per head is excellent for a small number of users.

A septic tank is typically constructed with a brick wall or blockwork containing cement mortar with a density [not less than 20cm (9 inches)] and a foundation floor composed of cement concrete in a 1:2:4 ratio. The internal and external surfaces of the walls, as well as the top of the floor, are plastered with a thick cement mortar 1:3 mix with a minimum density of 12mm (half an inch).

The inside corners of the septic tank are all rounded. At a rate of 2% of the cement weight, waterproofing agents such as Impermo, Cem-seal, or Accoproof are included in the mortar. Waterproofing agents should be included in the same ratio in the concrete as well as while creating the tank floor.

The floor of the septic tank is supported with a slope of 1:10 to 1:20 in the direction of the inlet side to simplify the process of collecting and eliminating dirt. It denotes that the floor on the outlet side will be higher in elevation than the floor on the inlet side.

Dimensions of Septic Tank Components

i) Septic Tank Length, Width, and Depth

Width = 750mm (minimum)

2 to 4 times the length width

Depth = 1000 to 1300mm (min below water level) + free board = 300 to 450mm

1800mm maximum depth + 450mm freeboard

Minimum capacity = 1 cubic meter (10 cubic feet).

ii) Detention period: In the process of designing the septic tank, the detention period should have been 24 hours. The rate of waste matter flow must be the same as the rate of influent flow.

iii) Inlet and outlet pipes: An elbow or T pipe with a diameter of 100 mm is submerged to a depth of 250-600 mm beneath the liquid level. An elbow or T type of 100 mm diameter pipe is submerged to a depth of 200-500 mm beneath the liquid level for the outlet. Choose pipes made of stoneware or asbestos.

iv) Septic Tank Baffle Walls: Reinforced Concrete (RC) hanging-type scum wall sets are installed in septic tanks for small tank sizes. The baffle walls are arranged next to the inlet. It is optional near the outlet.

The inlet baffle wall is set at a gapping of L/5 from the wall, where L is the wall’s length. Normally, the baffle wall is enlarged 150mm above the scum level and 400-700mm below it.

Scum floats at the water level in the tank because it is light. The density of the wall varies between 50mm and 100mm. Sludge discharge holes are located in the lower portion of larger tanks.

v) Septic Tank Roofing Slab: Depending on the size of the tank, an RC slab with a density of 75-100 mm is installed on the upper area of the septic tank. For inspection and desludging, circular manholes with a clear diameter of 500mm are arranged. The clear size for a rectangular entrance is kept at 600 X 450mm.

vi) Ventilation Pipe: A 50-100mm diameter cast iron or asbestos pipe is arranged as an outlet to discharge contaminated gases and for ventilation. The pipes should be extended 2 meters (minutes) above ground level. On the upper half of the ventilation pipe, a mosquito-proof wire mesh or cowl is arranged.

Method Statement for Septic Tank-Installation

- Excavation and preparation of the site

- Placement of the tank and connecting pipes

- Backfilling and compacting the soil

The installation process involves excavating and preparing the site for the septic tank. The tank is then placed in the prepared hole and connected to the inlet and outlet pipes. The pipes are installed at the correct angle to ensure proper flow and drainage.

Once the tank and pipes are installed, the site is backfilled and the soil is compacted to prevent settling.

Maintenance

- Regular inspections and pump-outs

- Waste disposal procedures

- Repairs and replacements

Regular inspections and pump-outs are required to ensure that the septic tank is functioning correctly. The frequency of pump-outs depends on the size of the tank and the number of occupants on the property.

Proper waste disposal procedures need to be followed to prevent damage to the septic tank and surrounding environment. Harsh chemicals, oils, and solids should not be disposed of in the tank.

Repairs and replacements may be necessary if the tank or pipes become damaged or worn over time. These repairs should only be carried out by qualified professionals.

Safety Precautions

- Personal protective equipment (PPE)

- Hazardous materials

- Emergency procedures

The installation and maintenance of septic tanks can be hazardous if proper safety precautions are not followed. Personal protective equipment (PPE) such as gloves, boots, and goggles should be worn at all times.

Hazardous materials such as sewage, chemicals, and gases may be present during the installation or maintenance process. Proper handling and disposal procedures need to be followed.

Emergency procedures should also be established in case of accidents or spills.

Conclusion

Septic tanks are an essential part of any property’s waste management system. A septic tank method statement is crucial to ensure that the installation or maintenance work is carried out safely, efficiently, and effectively. It is essential to follow all relevant laws and regulations and to take all necessary safety precautions during the installation and maintenance process.

FAQs

What is a septic tank method statement?

A septic tank method statement is a comprehensive document that outlines the procedures and precautions that need to be followed during the installation or maintenance of a septic tank.

Why is a septic tank method statement important?

A septic tank method statement is essential to ensure that the installation or maintenance process is carried out safely, efficiently, and effectively. It also helps to ensure that the work complies with all relevant laws and regulations.

Who should prepare a septic tank method statement?

A septic tank method statement should be prepared by a qualified professional with experience in septic tank installation and maintenance.

How often should a septic tank be pumped out?

The frequency of septic tank pump-outs depends on the size of the tank and the number of occupants on the property. A general guideline is to have the tank pumped out every 3-5 years.

Can I dispose of harsh chemicals in my septic tank?

No, harsh chemicals, oils, and solids should not be disposed of in a septic tank. These materials can damage the tank and the surrounding environment. Proper waste disposal procedures should be followed.

tag: septic tank method statement